Quality and environment

Pizeta’s Policy is one of continuous technological, organizational and commercial growth, while fully respecting environmental regulations.

The company’s ongoing improvement journey finds its most significant expression in the quality of the manufactured components and in the service provided to the customer.

Having entered some of the most demanding sectors, Pizeta recognized the need to deliver products of even higher quality. This drove the owners, Rolando Zerbato and Roberto Peron, to invest in a superior management system. The transition to ISO 9001 certification was thus successfully achieved.

In 2022 Pizeta introduced its own environmental policy aimed at controlling and reducing the environmental impacts generated by its activities, and obtained ISO 14001 certification in 2023.

Responsibility toward the environment represents one of the cornerstones of the company’s strategy, on a par with the attention devoted to the quality of products and services supplied to customers. Pizeta is aware of the need to integrate its industrial activities as harmoniously as possible with the surrounding territory; it fully recognizes the importance of its actions in relation to the various environmental aspects that concern it and the impacts it may generate.

Therefore, considering commitment to the environment as an integral part of its operations, Pizeta has decided to adopt its own Environmental Management System compliant with the requirements of the ISO 14001 standard, pursuing the following objectives:

- protection of the environment, including prevention of pollution, sustainable use of resources, and mitigation of climate change

- control of its environmental aspects (waste, emissions, noise, effluents, resource consumption, etc.) through the assessment and, wherever possible, the reduction of significant environmental impacts generated by Pizeta in the course of its activities

- full compliance with all applicable environmental protection legislation and with any other compliance obligations toward interested parties

- continuous improvement of its environmental performance through:

- adoption of the Best Available Techniques (B.A.T.) in internal production processes

- improved management of the waste produced

- definition of environmental objectives at company level

- identification of risks associated with work activities aimed at reducing environmental impacts

- training of all employees so that they possess the knowledge and awareness necessary to apply the principles of this policy in their daily activities in order to safeguard the environment

- allocation of human and financial resources to achieve the set objectives

- communication of the environmental policy to all interested parties

Commitment to respect and care for the environment constitutes a fundamental component of our work, and the achievement of environmental objectives must remain a constant priority.

Production control is essential to limit the amount of scrap generated and therefore to reduce the environmental impact.

Currently, quality control activities are distributed between incoming raw material and shipment of finished goods.

The first phase concerns incoming raw bars, for which form, dimensions and chemical composition (matching customer specifications) are verified.

After machine set-up, the Quality Control department (Q.C.) carries out approval of all drawing dimensions and notes, reporting any anomalies to the set-up personnel for correction. Once approval is granted, Q.C. prepares the Control Plan (C.P.) for the in-process inspection operators. The Control Plan is entered into a dedicated software that defines both the inspection frequency and the instruments to be used. To monitor and anticipate potential drifts or out-of-tolerance parts, the software can alert to ongoing issues through the use of statistical indices such as Cp and Cpk. These data can be converted into statistical reports whenever requested by the customer.

After production, parts are washed in two solvent-recycling washing machines; subsequently, they can undergo 100% visual inspection and gauging, both in a standard environment and in a cleanroom.

When external treatments are involved, control extends to those processes as well, through verification of the treatment certificate issued by the processor and visual/dimensional checks to highlight any issues.

Each lathe is equipped with its own PC-monitor that displays real-time production progress and allows operators to record measurements directly at the machine. Previously saved records are also displayed on these monitors, enabling the operator to view any dimensional drifts on the dedicated graphs.

In the production area, inspection islands are also distributed — one for each operator — equipped with measuring instruments that cannot be kept directly at the machine (such as height gauges and bulkier devices).

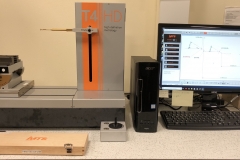

The main control room is air-conditioned and equipped with extremely advanced and precise instruments. In the first months of 2014, the introduction of a coordinate measuring machine (CMM) further enhanced the already comprehensive range of measuring equipment. In 2017 a new profilometer was added, rounding out the instrument portfolio and making previously very difficult measurements significantly easier to perform.

In order to eliminate some bottlenecks in the inspection phase, in 2021 and 2022 two new Vici Vision digital optical comparators were installed and a second Mitutoyo coordinate measuring machine was added.

The main instruments present in the control room are the following:

- Mitutoyo Crysta Apex S544 and V544 coordinate measuring machines

- Vici Vision M306 digital optical comparators

- TESA Rugosurf 90-G roughness tester

- IMTS T4HD profilometer

All instruments are periodically verified by an external accredited company, which also provides the software for managing calibration deadlines and certificates.